References

Audi AG

The Audi AG and the HAW Ingolstadt are working with a mobile manipulator MM-800, already doing test runs under normal production conditions.

The robot is used for picking parts from the storage as part of the production preparation. This project has two main objectives:

This new level of automation is meant to help handling the increasing number of different picking processes in production preparation. The mobile manipulator is almost as flexible as a worker but can be directly linked to the process control system. Its error probability is therefore significantly lower which will reduce costs created by mistakenly selected and assembled parts.

Furthermore the robot relieves the human workers from handling bulky or heavy parts.

BSH Bosch and Siemens Homeappliances

An omnidirectional robot tests dishwashers in continuous operation in a lab of Bosch and Siemens Homeappliance. The whole robot was designed and built by Neobotix according to the customer's requirements. It uses four Neobotix OmniDriveModules to maneouvre in its very narrow workspace. A UR10 robot arm from Universal robots is mounted on a vertical lift axis. This enables the robot to operate dishwashers at two different levels.

In order to achieve highest efficiency, the robot operates 24/7. Ceiling mounted conductor rails supply power to the robot and also provide the connection to the safety system of the workspace as well as to the overall control system.

Nussbaum Technologies

Nussbaum Technologies develops and installs automatic parking systems for cars. One of those systems employs an omnidirectional mobile platform to fetch cars from a parking lot and bring them to the customers.

Localisation and accurate navigation of this platform, which weighs several tons, is handled by our reliable robot control software PlatformCtrl.

The first of these car vending systems was opened for Carvana in the USA at the beginning of 2016. Now customers can pick up a car as easy as using a jukebox.

ProSiebenSat.1 Media / N24

The N24 news studio has been on-air from October 2008 until April 2021, using Neobotix hardware. Eight camera robot systems were operating in Berlin:

- Two dollys running on a C-shaped rail of 9 m diameter under the ceiling of the main news studio each carried a vertical lift unit with a pan-tilt-head.

- Three more pan-tilt-heads were mounted on fixed pedestals on the floor of the news studio.

- The last three systems were used in a greenscreen studio, each consisting of a lift column, a pan-tilt-head and a localisation extension. These three camera robots were connected to the virtual graphic system of the studio.

All these camera robots had been especially developed by Neobotix for this application. ArmCtrl was used to control the motion of all axes.

SAV Mittweida

The automation specialist SAV Mittweida uses a transport robot MT-400 to supply a machine with heavy parts.

The MT-400 fetches the parts from several roller conveyors and feeds them into the machine's supply buffer. This makes the machine independent from the output rhythm of other production steps and allows it to always run at full capacity.

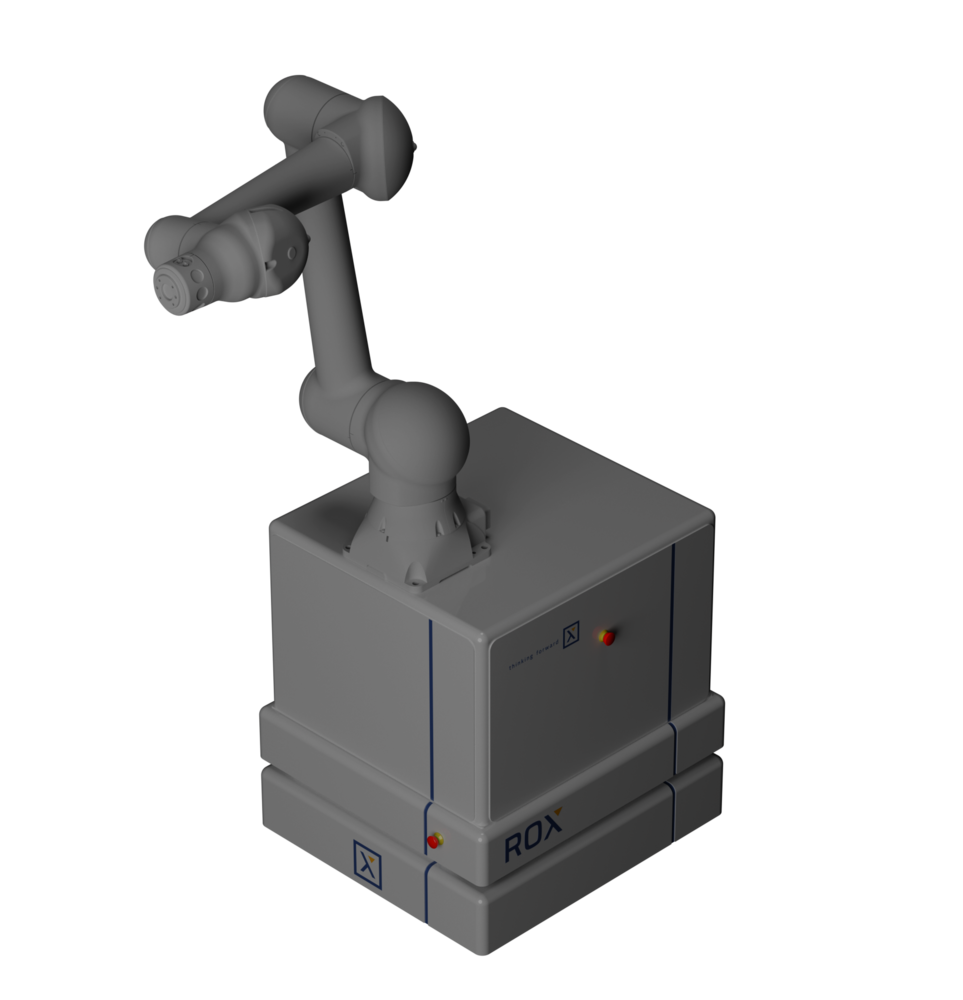

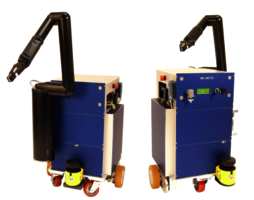

SmartFactory - EMROX

We are pleased to announce that we have successfully delivered one of our state-of-the-art mobile manipulators EMROX with integrated Yaskawa HC10 cobot arm to the renowned SmartFactory.

SmartFactory is a leading centre for research and development of Industry 4.0 solutions. Their vision and commitment to innovative technologies make them an ideal partner for the implementation of our advanced robotics solutions.

The EMROX is another example of our excellence in the robotics industry. With its advanced robotic technology and ability to perform complex tasks in dynamic production environments, the EMROX will undoubtedly help to further increase efficiency and productivity in the SmartFactory. This project emphasises our commitment to providing high-quality and forward-looking solutions that drive Industry 4.0.

We would like to thank SmartFactory for their trust in our technology and look forward to further expanding our collaboration to push the boundaries of industrial automation together.

For more information about the EMROX robot and our products, please do not hesitate to contact us.

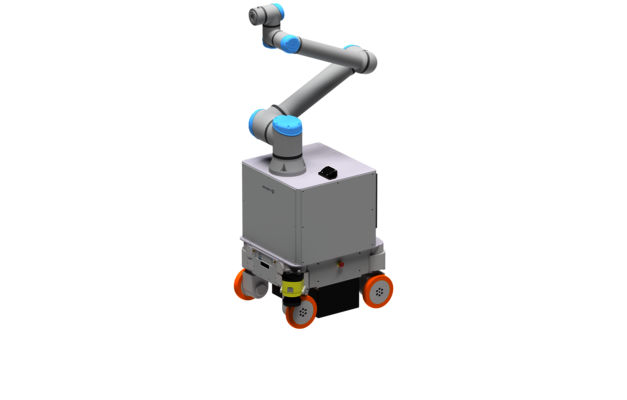

Carnegie Mellon University (CMU) - MP-400

We are proud to maintain a good relationship with Carnegie Mellon University (CMU) and are pleased to announce that, in addition to an MPO-500 mobile robot, two MP-400s have been in use there since mid-2023.

These two MP-400s are extensively equipped with LiFePO4 batteries, an automatic charging station and wireless emergency stop systems. Thanks to ROS 2, they are also ideally equipped for future research projects and developments.

The integration of our MP-400 is an outstanding example of the innovative use of technology in education and research. The CMU- provides the opportunity to explore the latest developments in robotics and artificial intelligence and showcases the progress made through our joint work in an impressive way.

Our robot has proven to be extremely reliable and capable, and the collaboration with CMU has helped to achieve groundbreaking results in various areas of research.

We appreciate the opportunity to work with CMU and we are excited by the way our technology is presented. We firmly believe that this collaboration is of great importance to both the university and our company.

We look forward to further successful projects and are excited about future developments.

Deakin University - MPO-700

For its use at Deakin University in Australia, an omnidirectional MPO-700 was prepared for the integration of a Cobot UR10e arm and additionally equipped with LiFePO4 batteries. This innovative battery technology has further improved the robot's performance level and led to impressive results. The battery offers high energy efficiency, advanced charging technology and intelligent energy management, resulting in a significant increase in operating time and optimised use of the robot.

With our robot, nothing stands in the way of Deakin University's research work and we are pleased to have played a part in it.

Instituto Italiano Di Tecnologia

Update:

Even after 9 years the unmodified MM-500 from Neobotix is still running to the complete satisfaction of the Instituto Italiano Di Tecnologia.

The institute uses mobile robots for the research and development of human-centered robot technologies. The focus is on the development of robot systems to enhance human capabilities through improved interfaces. Research priorities include robot-assisted surgery, human-robot interfaces and assistance systems for people with disabilities.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

On the 22.02.2010 a mobile manipulator MM-500 was handed to the italian Instituto Italiano Di Tecnologia.

Different from all former projects, this time no customisations were required and the robot was produced in the shortest possible time.

This MM-500 SK thus was the first Neobotix robot that was ordered directly "off-the-shelf".

The MM-500 IIT does not only feature a 7DOF LWA3 robot arm made by Schunk and a gripper with quick change flange, but also a completely new force-torque-sensor. This sensor was also developed by Schunk.

Two mobile robots MP-500 for the Karlsruher Institute of Technology (KIT)

On October 2019 the KIT received the second mobile robot MP-500 from Neobotix for the dismantling project of nuclear power plants. MP-500 will measure closed nuclear power plants autonomously so that the dismantling can be planned. Important for the choice of the mobile robot MP-500 were its dense and easy to clean shell and the robust, easily modifiable structure.

The ROS control of the robot also includes an extensive simulation.

ASTRI - Hong Kong Applied Science and Technology Research Institute Company Limited

Hong Kong Applied Science and Technology Research Institute (ASTRI) adopts the Digital and Physical Twins approach in the development of the Collaborative Mobile Manipulator (CMM) based on Neobotix MMO-500.

Digital Simulation is conducted on the Digital Twin of the CMM for System Validation before Physical Execution on its Physical Twin. The Mecanum wheels of the CMM enable the movement in any direction and hence the workspace of the Manipulator is significantly enlarged. In addition, the CMM is equipped with LIDAR sensors, vision systems and an end-effector for conducting autonomous navigation, parking/unparking and pick-and-place in a collaborative human-robot working environment for the support of Smart Factory in the era of Industry 4.0.

European Space Agency

The Dutch facility of the European Space Agency is working with a Mecanum robot MPO-500. The omnidirectional robot is used for simulations of complex movements in space.

Carnegie Mellon University

The Personal Robotics Lab at Carnegie Mellon University has decided to use a Mecanum robot MPO-500 as new base for its robot butler HERB.

This provides HERB with more stability and also, even more important, omnidirectional manoeuvrability. His new Mecanum wheels enable it to instantly move into any direction.

The MPO-500's feature set convinced the scientists: "The MPO-500 is one of the finest omni-directional bases we have seen. It is rugged, customizable, and perfect for navigating tight spaces, and for mobile manipulation."

MMO-500 in China

A mobile manipulator MMO-500, based on the Mecanum robot MPO-500, will soon be running at a university in China.

The mobile robot features a Schunk light weight arm LWA4P. It can be equipped with either a standard parallel gripper or an advanced 3-finger gripper from Robotiq. This makes it a very versatile solution for a wide range of applications.

DHBW Ravensburg

The DHBW Ravensburg, a technical university, uses a mobile robot MP-400 as common platform for very different projects.

This allows the students of the technical faculty to implement, test and present their research and development results on an actual robot.

OC Robotics

OC Robotics, a british robotics company, uses an MPO-700 as omnidirectional base for their mobile snake-arm robot.

The 1.5m robot arm can follow a 3D path and explore the most hidden spaces of structures that other robots cannot reach. The omnidirectional base automatically follows the snake-arm.

One of these robot systems is now used by the University of Oxford's Mobile Robotics Group for research.

Bristol Robotics Laboratory

The Bristol Robotics Laboratory (BRL) is the most comprehensive academic centre for multi-disciplinary robotics research in the UK. It is a collaborative partnership between the University of the West of England (UWE Bristol) and the University of Bristol, and home to a vibrant community of over 150 academics, researchers and industry practitioners.

Bristol Robotics Laboratory’s omnidirectional manipulators MMO-700 UR10 will support a range of research and student training projects within its FARSCOPE Centre for Doctoral Training.

Fraunhofer AGP

The Fraunhofer AGP (application centre for large structures in production engineering) uses an omnidirectional mobile manipulator MMO-500 UR10.

The robot will be used in different research projects. Its goal is to try out new applications for mobile robotics in industrial production environments.

ESB Business School Reutlingen

The ESB Business School, a part of Reutlingen University, uses a mobile robot MP-700 with an integrated Baxter robot. The system is used for research concerning human machine interaction and cooperation in production processes.

University of Vienna

The University of Vienna now uses a mobile robot MP-400 as automatic transport system in its training workshop. The robot allows students to develop new types of material transfer systems and to immediately test them under real-world conditions.

CSIRO

The Australian research institute CSIRO uses an omnidirectional manipulator MMO-500 for its research in service robotics. The MMO-500 is based on a Mecanum robot MPO-500 with a UR10 robots arm from Universal Robots mounted on top.

The original controller box of the UR10 was integrated. This allows the advanced and intuitive control system of Universal Robots to be used without limitations.

University of Oxford

The University of Oxford uses an omnidirectional robot MPO-700 for its research projects. This robot was heavily modified to suit the university's requirements.

Beside having a completely black cover, the robot also features some additional components like a Neobotix IOBoard and a remote emergency stop system.

Its ability to recharge autonomously at an automatic charging station allows this robot to operate completely without user interaction.

University Ravensburg-Weingarten

The University Ravensburg-Weingarten also uses an omnidirectional robot MPO-700 as base of a new service robot. The basic platform will be equipped with a vertical lift that carries a light-weight robot arm. Several sensors will enable the robot to analyse its environment. The robot's main task will be in supporting people with physical handicaps.

Aalborg RVMI

The Robotics, Vision and Machine Intelligence laboratory of Aalborg University is already using two mobile robots MP-700 for its research activities, developing new solutions for automation and material flow. Their "Little Helper" is equipped with a robot arm from Adept or KUKA and operates fully autonomously.

BioRob

The omnidirectional MPO-700, which has been individually customised for BioRob, will be equipped with a linear axis and one of BioRob's bionic light weight robot arms. Several cameras and other sensors will also be integrated. The robot will then be used to create high accuracy 3D scans of large objects, e.g. items on display in museums, without the need to move them to special studios.

LAAS-CNRS

This robot is a customised omnidirectional robot MPO-700 with a powerful integrated vertical lift unit. The lift can move two KUKA LBR4 robot arms, two grippers, 10kg load and a pan-tilt-head with a complex sensor equipment. Thanks to this function, the robot can manipulate objects on normal table height and can also pick up objects from the ground in front of it.

The vertical axis is strong and rigid enough to handle a load of more than 50kg at a distance of 600mm from the arm flanges.

The LAAS is a department of the French national research organisation CNRS. Its focus is on information technology and complex systems.

By the way:

After the delivery of the MPO-700 in June 2011 there will be two Neobotix robots at the LAAS. We delivered the first one in February 2005 and it is still used daily.

RoboGasInspector

The research project RoboGasInspector will be using a mobile platform MP-500 which was handed over to representatives of the Kassel University on the 3rd of December 2010.

This project is part of the research initiative Autonomik and will be working on methods for autonomous remote detection and localization of hazardous gas leaks in production plants.

The MP-500 will be used as a prototype for tests in the lab. It will be equipped with a variety of different sensor systems.

Szechenyi Istvan University

Four mobile platforms MP-500 were handed to representatives of the Hungarian Szechenyi Istvan University on the 1st of December 2010.

This university is currently building up a new laboratory of automation. The focus of this lab will be on tasks of robot cooperation and interaction.

For this purpose the project partner Nor-Service provided two ABB industrial robot arms which will be working with the mobile platforms.

The official opening ceremony of the new lab was in early 2011.

There are already some videos of these robots available on YouTube. You can get an impression of the ROVIS-System in this video.

ImRoNet

The project ImRoNet focused on human-machine-interaction, especially with teleoperated robots.

Neobotix provided a mobile platform which was equipped with an additional computer, an arm and unique sensor system.

A mobile manipulator MM-500 was also used. This robot had a panel-PC, made by Beckhoff, attached to its arm and is meant to make critical maintenance work easier by providing supporting information via augmented reality.

BetoScan

The aim of the BetoScan project was to develop an autonomous scanner system for detecting and mapping damages on laminated concrete floors such as floors of a multi-storey car park, bridges and industrial floors.

The project started on 1st January 2007 and finished on 31st December 2009. The role of Neobotix in BetoScan was to develop and provide a mobile robot that can successfully navigate through a large area where the lack of unique landmarks effects navigation difficulties.

The robot is waterproof and designed for fast installation with user-friendly user interface. It has high repeat-accuracy which makes it robust and reliable.

The mobile platform is based on the MP-500 and features different modifications to best suit the needs of this complex task.

DESIRE

A large number of companies and research institutes was cooperating for four years to unite the different state-of-the-art modules that have been developed in the field of robotics. The Desire project has build a platform that contains all these modules.

Its basic idea distinguished Desire from other projects. Desire was not meant to achieve a quantum leap in a specialised field of research or solve a single task but to combine all the different modules that have been developed separately and to make them reliable for everyday use.

After the end of this project, the achieved knowledge and techniques will be used by other research projects as a starting point.

Neobotix built the omnidirectional platform and furthermore designed and realised the robot's complete body as well as the carbon fibre cover.

INDIGO

In the INDIGO-Project a mobile robot has been developed, that is capable of natural interaction with humans.

During the project which ran from February 2007 until February 2010 Neobotix cooperated with several partners from all over the world. Besides the Albert-Ludwig Universität Freiburg also the Foundation for Research and Technology - Hellas, the University of Edinburgh, the University of Geneva, the Acapela Group from Belgium and the american Hanson Robotics contributed to the project's success.

Neobotix provided a mobile robot of type ME-600 which was equipped with a special robotic head from hanson robotics.

Together with specially adjusted cameras and microphones and the highly capable software of the other partners it is now possible to interact with this robot like never before.

Care-O-bot 3

Neobotix engineered and built the omnidirectional platform for the Care-O-Bot 3 which has been presented to public in June 2008. As supplier for the Fraunhofer IPA Neobotix also build the basic, inner mechanics and electrical system of the robot's body.

The two-axis drives have been developed especially for the IPA and provide almost unlimited movements in the plane due the possibility of rotating every wheel independendly around its vertical axis. A lithium ion battery provides good runtimes despite the large number of drives and computers aboard.

Some other important features are the flexible, soft skin of the robot's movable body and the sensor head with stereo and 3D-camera systems, which can be pointed both forward and backwards. A light weight arm from Schunk with a three finger hand can be used for efficient interaction with the environment.

In the next years the Care-O-Bot 3 will be continuously under development to solve both known and new tasks in domestic service robotics.

rob@work 2

The new rob@work 2 is working at the Fraunhofer IPA since July 2008. This robot belongs to the follow-up research project of the rob@work which was also based on a mobile platform from Neobotix (see below).

The rob@work 2 is built from a version 3 MP-700 and offers more functions and several improvements in a more compact and appealing design. A second laser scanner now enables the robot to permanently monitor its whole environment without blind spots.

A modern light weight robot arm from Schunk is mounted onto the new platform. This 7-DOF arm is extremely agile and already contains all the required electronics. Without the big electric control cabinet required by older manipulators there is more space on the platform's cargo area to store objects or to mount other application-specific components.

Aalborg University

In January 2008 a mobile platform of type MP-700 was shipped to the institute for production at the Aalborg university in Denmark. Equipped with a 6 DOF robot arm Adept Viper s650 the robot will be used for research on the field of mobile manipulation. To allow the industrial robot arm to move autonomously to several work places and be reliably used there the basic platform can dock at an automatic charging station.

The current status of the several research and university projects that use the "Little Helper" can be found under robotics-automation.aau.dk. The first industrial test application and later the full installation are scheduled for late 2009 and 2010.

CEA - ANSO

The objective of the ANSO-project, in which the Commissariat a l'Energie Atomique is working, is to create a software platform for multimedia networks. Additionally the possibilities for physical interactions via the network will be improved.

The mobile robot that was built for this project consists of a mobile platform MP-600 and a 6 DOF manipulator of type ARM from Exact Dynamics.

With this combination the ARM-manipulator, which was originally designed to be mounted on electrical wheel chairs, now can be used under completely new conditions.

Here you can watch a video of this project.

University of Bremen

On 17.03.2006 Neobotix delivered a mobile plattform MP-600 to the University of Bremen.

This platform will continue the long row of research projects done by the institute of automation in the field of robotics.

When equipped with an 6 DOF robot arm the platform will be used in research on mobile manipulation.

ASSISTOR

Since 2003 Neobotix was been participating in the joint research project ASSISTOR sponsored by the BMBF. This project was carried out by Fraunhofer IPA, ELAN, Reis Robotics, Schunk, Sick, Vision&Control and Neobotix.

In the context of mechatronics and robotics the project had the following objectives:

Development of robust mechatronic systems for a direct man-machine interaction

Development of configurable sensor and control systems for a safe man-machine cooperation

Working out the basics for the approval and standardisation of robots in a man-machine interaction

Building up of demonstrators for testing usability and robustness

Neobotix presented the results of its work in the field of mobile robotics with a robot arm in November of 2005.

university of Düsseldorf

Neobotix delivered a mobile platform to the Fachhochschule Düsseldorf used at the research project 'Ego Secundus'.

The goal of this project is to develop a new way of communication between people who are far apart.

The platform, a modified MG-400, is exclusively destined for telepresence and does not have a laser scanner. Because of this it is unable to move autonomously.

Only when a user has logged in via the internet, the robot can be moved.

MORPHA - Care-O-bot II

The core-idea of the project MORPHA was to equip intelligent mechatronic systems, particularly robot assistants or service robots, with the ability to communicate, interact and collaborate with human users in a natural and intuitive way.

The use of robots in household applications is driven by different motivations. One of them is the aspect of comfort. More important, however, is the increasing number of households with sick, disabled or aged people that supports the necessity of the application of mobile robots for physical assistance activities in households. Robots are expected to work in the direct living surroundings of people. For this reason, the most natural interaction between people and machines is of the utmost importance.

A robot assistant will be able to carry out simple household activities partly in interaction with people. The activities could include such tasks as, for example, transportation, cleaning or laying a table. The robot has to move in different rooms within an apartment without colliding with people or furniture.

The Fraunhofer IPA uses an MP-600 platform with a special robot arm as a demonstrator.

Mor informationen about Care-O-bot and Care-O-bot II can be found on the project's homepage.

University of Hamburg

TAMS is an acronym for 'Technische Aspekte Multimodaler Systeme'.

The general purpose of this institute is to develop methods and to implement integrated real-time systems for the acquisition, processing and application of information gathered via multiple channels such as visual input, speech and sound, touch through action, etc.

The research topics include multi-modal control architecture, sensor-based manipulation, robot learning, human perception, man-machine-interaction, computer architecture and VLSI design technologies.

Application areas include service robots, active media, intelligent sensors and advanced nano-manipulation platforms.

University of Bielefeld

The complete automation of sampling and the subsequent sample management in mammalian cell cultivations on a pilot scale is the subject of this work. In order to achieve this goal, a sensor-guided industrial robot arm (platform MP-L655 with a Mitsubishi PA-10 manipulator) is used.

The robot arm is equipped with a hand-camera, a force/torque sensor and an electrical gripper. In addition to the normal laboratory equipment, a computerized automatic sampling station, a pipetting device and a cell counter are also needed. The robot takes a sample tube filled by a sampling device to different machines. The cell density is determined by the cell imaging system. Bar-code scanner and cell counter deliver the off-line data to the device control system.

After processing, off- and on-line data are stored and visualized in the process control system that is connected to a network and a modem. The whole system is controlled by a device control system.

rob@work

The objective of the project 'Marktorientierte Vorlaufforschung (MaVo)' was the development of methods and products that ensure robustness and flexibility based on artificial intelligence. Moreover, all solutions pursued the objective of reducing unit costs.

Fraunhofer IPA used our MP-700 with a Mitsubishi PA-10 manipulator as a demonstrator for this project. The project rob@work was part of the MaVo project.