ROX-Diff

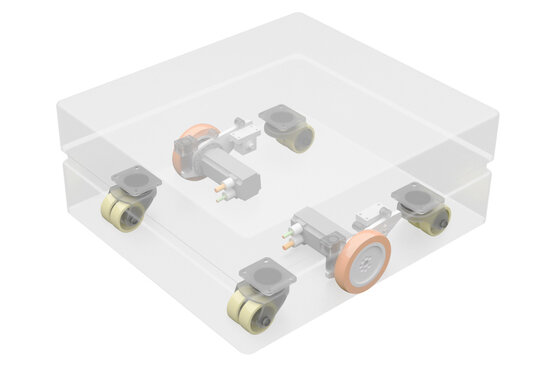

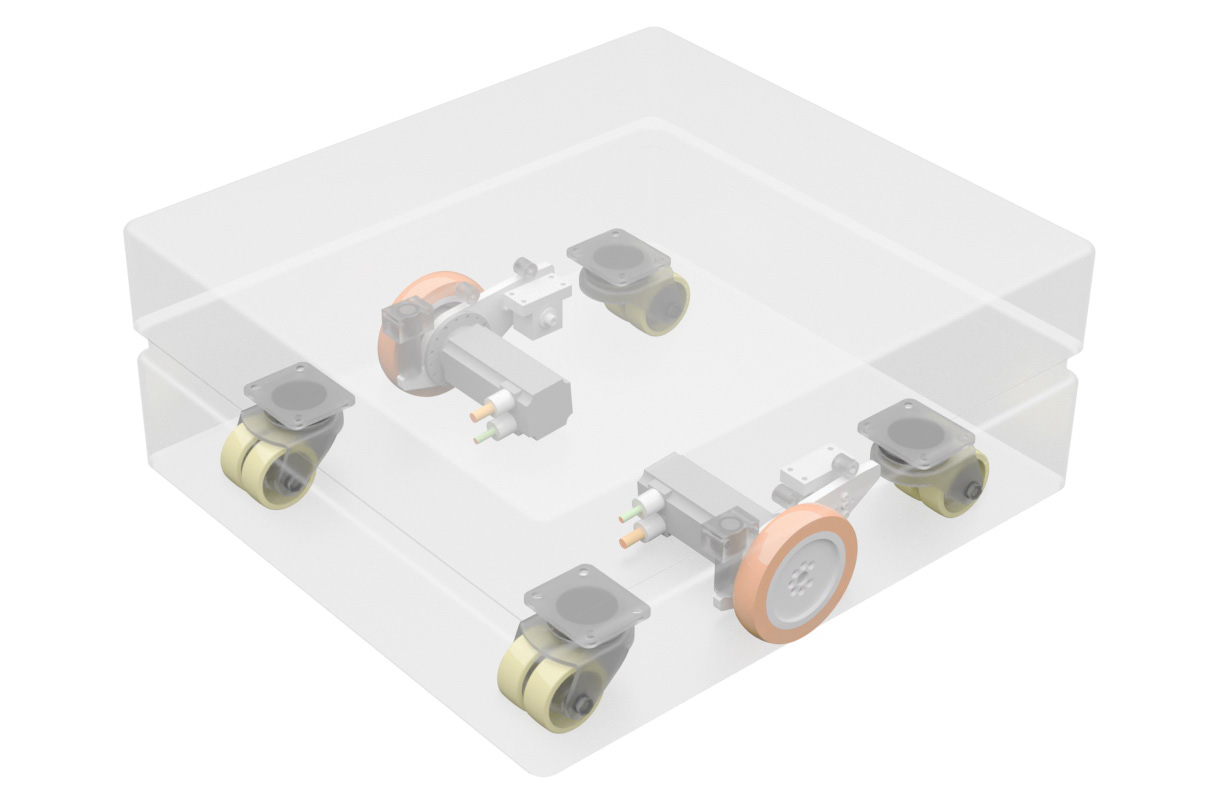

ROX Platform With Central Differential Drive

The central differential drive is one of the most common kinematic configurations in AMRs, along with the three-wheel setup. It consists of two independently controlled drive wheels, which are mounted on the left and right corners of the platform center. The actual load is supported by passive steering casters, one at each corner of the platform in the case of the ROX.

This configuration offers several advantages:

- It is a cost-effective and energy-efficient drive system.

- The ability to rotate in place provides the robot with high mobility, even in confined spaces.

- Thanks to its suspension system, the robot can easily navigate small steps and gaps and can handle most industrial floor surfaces with ease.

On the other hand this design comes with very few limitations:

ROX-Diff

Basic configuration

Description

Turnkey system: 2x motors, 1x Sick S300 expert scanner, sealed lead battery 24V/50Ah, wireless joystick, manual charger, on-board computer (Intel i5, 8 GB RAM, >200 GB SSD, WLAN), ROS, documentation, CE conformity declaration

1 day training

Description

In Heilbronn for up to 3 persons

inclusive catering

inclusive catering

Basic support

Description

3 month support (Telefon/E-Mail)

Automatic charging station

i7 on-board computer

Description

Intel Core i7, 16 GB RAM, 400+ GB SSD

IOBoard

Second laser scanner

Description

Extended support

Description

Additional 6 months support

by telephone/e-mail/update

by telephone/e-mail/update