Enabling flexible production with progressive automation

Every component of Elite’s cobots is a result of independent R&D efforts, such as underlying operating

system, the embedded hard- and software, the process package, the top-of-the-line computing power, and even the joint module technology.

The EC series has garnered a good reputation in the industry thanks to its stable operation, smooth drag, flawless functionality, and high cost-performance ratio. Furthermore, leading collaborative robot projects have already integrated the EC series in multiple

industries, including auto parts, 3C electronics, metal processing, home appliances and electric power.

Elite’s cobots have several competitive advantages: For example a simulation to ensure product stability and low self-weight-to-load ratio. Elite also has a world-class pre-sales and after-sales team with rich experience in robot usage and a deep understanding of the application scene.

The latest arrival of Elite Robots collaborative robots family, the new CS Series, is a platform-level cobot based on a new software & hardware infrastructure and a wholly redesigned user interface, providing enhanced safety, ease of use and high expandability, all while ensuring a rapid return on investment.

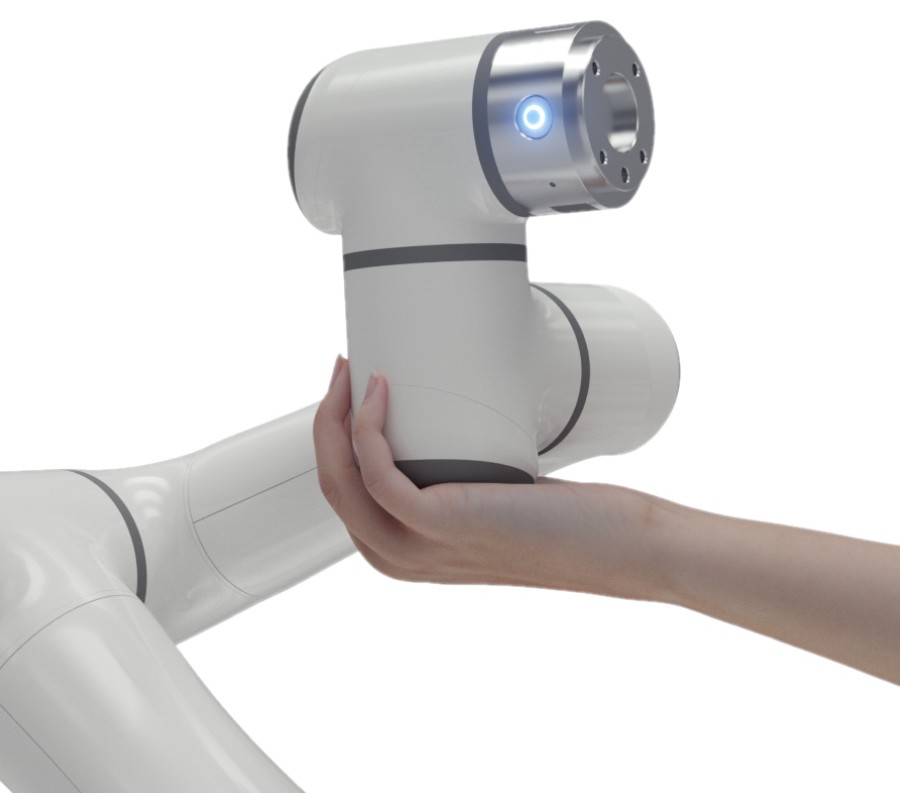

Six-Axis collaborative cobot with infinite motion possiblilities.

Safe:

They can work side by side with humans without a safety fence, possess a high level of reliability and safety.

Lightweight:

Collaborative robots that weigh less and offer much.

Efficient:

Maximum straight line speed up to 2.8 m/s , high working productivity, smooth trajectory e consistent action.

ROS Programmable:

All collaborative Elite robots have a ROS package which includes drivers and a 3D model of the cobot.

EC66

The Elite Arm EC66 is easy to integrate into a workstation as its light weight and versatility make it ideal for medium duty applications.

In addition, the EC66 can be a very good choice for a detachable workstation.

For more information, please do not hesitate to contact us here.

EC612

The EC612 is a powerful arm. It can lift up to 12 kg without losing accuracy. Precision as well as range have been most important for the development of this arm. The range is 1304 mm which makes the robotarm best suitable for a greater distance between work areas. The Elite Arm EC612 can be used individually for any kind of work.

For more information, please do not hesitate to contact us here.

EC616

The payload of 16 kg and the weight of 32.5 kg make EC616 both the strongest cobot and the one with the best load-to-weight ratio of the EC Series line-up. It’s an ideal match for applications ranging from palletizing to machine tending and welding, as well as the perfect solution for industries such as semiconductors.

For more information, please do not hesitate to contact us here.

CS66

CS66 is ideal for simplifying a wide variety of processing tasks to the extreme. Its ability to support a very large number of EoATs and other equipment and an unmatched ease of use make this cobot the must-have choice for the smoothest possible automation of machine tending, quality inspection, screw-driving and more!

For more information, please do not hesitate to contact us here.

CS612

The CS612 is the perfect choice for smoothly automating tasks such as palletizing, machine loading, and welding, as well as seamlessly implementing effective AMR/AGV robotic mobility solutions. Thanks to its IP65-rated and sturdy arm it can guarantee long uptimes even in the harshest environments.

For more information, please do not hesitate to contact us here.

CS620

With a 20 kg payload, a dual connector with a 5A output source that can handle multiple effectors simultaneously, and a leading 1800 mm radius, CS620 can flawlessly perform the most demanding tasks.

For more information, please do not hesitate to contact us here.

CS625

The 25 kg payload and the 5 A I/O tool make the CS625 the best and most economical alternative to industrial robots. Bring safety and power to your workshop!

For more information, please do not hesitate to contact us here.

Technical data EC series

| Model | Parameter | EC66/EC66M | EC612/EC612M | EC616/EC616M |

| Robot arm | Max. Payload | 6kg | 12 kg | 16 kg |

| Working Radius | 914 mm | 1304 mm | 954mm | |

| Repeatability | ±0.03mm | ±0.05mm | ±0.03mm | |

| Number of Axis | 6 | 6 | 6 | |

| Range of Motion(Axis 1-6) | ±360° | ±360° | ±360° | |

| Joint Speed J1-J2 | 150°/s | 120°/s | 120°/s | |

| Joint Speed J3 | 190°/s | 150°/s | 150°/s | |

| Joint Speed J4-J6 | 260°/s | 210°/s | 210°/s | |

| Maximum Speed | 2.8 m/s | 3.2 m/s | 2.8 m/s | |

| Power Consumtion | 250W | 435W | 435W | |

| Net Weight | 17.5 kg | 33.5 kg | 32.5 kg | |

| Tool Side IO | 2 x DI, 2 x DO, 1 x AI, 1 x AO | |||

| Robot Arm Power Supply | 48 V | |||

| Length of the Cable | 5.5 m | |||

| Installation Method | Any Angle | |||

| Certification | EN ISO 10218-1 | |||

| Body Material | Aluminum, Steel | |||

| Operation Temperature | 0 ℃ to 50 ℃ | |||

| Working Environment Humidity | 5 %~95 % (non-condensing) | |||

| IP Protection Class | IP54 | |||

| Controller | Control Cabinet Size | 505 x 448 x 245 mm | ||

| Control Cabinet Material | Aluminum, Steel | |||

| IP Protection Class | IP44 | |||

| I/O ports | 16 x DI, 16 x DO, 2 x AI, 4 x AO | |||

| Communication ports | 1 Ethernet ports,1 RS485/RS232, 1 USB 2.0 | |||

| Communication Interface | TCP/IP, Modbus TCP/RTU, EtherNet/IP, Profinet, CCLink | |||

| Control Cabinet Weight | 17 kg | |||

| Control Cabinet Power Supply | 100-240 VAC, 50-60Hz (M: 19-72VDC) | |||

| Teach Pendant | Size | 290 x 225 x 118 mm | ||

| Screen display size | 12.1" | |||

| Resolution | 1280 * 800 | |||

| Material | Aluminum, Plastic | |||

| Net Weight | 1.8 kg | |||

| Length of the Cable | 5.5m | |||

| IP Protection Class | IP54 | |||

| Input method | Capacitive touch-screen | |||

Technical data CS series

| Model | Parameter | CS66 | CS612 | CS620 | CS625 |

| Robot arm | Max. Payload | 6kg | 12 kg | 20 kg | 25 kg |

| Working Radius | 914 mm | 1304 mm | 1800 mm | 1500 mm | |

| Repeatability | ±0.03 mm | ±0.05 mm | ±0.1 mm | ±0.08 mm | |

| Number of Axis | 6 | 6 | 6 | 6 | |

| Range of Motion(Axis 1-6) | ±360° | ±360° | ±360° | ±360° | |

| Joint Speed J1-J2 | 150°/s | 120°/s | 125°/s | 125°/s | |

| Joint Speed J3 | 180°/s | 150°/s | 150°/s | 150°/s | |

| Joint Speed J4-J6 | 230°/s | 180°/s | 210°/s | 210°/s | |

| Maximum Speed | 2.8 m/s | 3.4 m/s | 3.9 m/s | 3.3 m/s | |

| Power Consumtion | 250W | 435W | 625W | 625W | |

| Net Weight | 20 kg | 34 kg | 60 kg | 58 kg | |

| Tool Side IO | 4 x DI, 4 x DO, 1 x AI, 1 x AO | ||||

| Robot Arm Power Supply | 48 V | ||||

| Length of the Cable | 5.5 m | ||||

| Installation Method | Any Angle | ||||

| Certification | EN ISO 13849-1, PLd Category 3, EN ISO 10218-1, CE UL CR KCs RoHS | ||||

| Body Material | Aluminum, Steel | ||||

| Operation Temperature | 0 ℃ to 50 ℃ | ||||

| Working Environment Humidity | <90 % (non-condensing) | ||||

| IP Protection Class | IP65 (IP68 upgradable) | ||||

| Controller | Control Cabinet Size | 505 x 432 x 257 mm | |||

| Control Cabinet Material | Aluminum, Steel | ||||

| IP Protection Class | IP54 | ||||

| I/O ports | 24 x DI, 24 x DO, 2 x AI, 4 x AO | ||||

| Communication ports | 3 Ethernet ports,1 RS485, 1 MiniDP, 1 USB 2.0, 1 USB 3.0 | ||||

| Communication Interface | TCP/IP, Modbus TCP/RTU, EtherNet/IP, Profinet, OPCUA | ||||

| Control Cabinet Weight | 17kg | ||||

| Control Cabinet Power Supply | 100-240 VAC, 50-60Hz | ||||

| Teach Pendant | Size | 301 x 232 x 54 mm | |||

| Screen display size | 12.1" | ||||

| Resolution | 1280 * 800 | ||||

| Material | Aluminum, Plastic | ||||

| Net Weight | 2.1 kg | ||||

| Length of the Cable | 5.5 m | ||||

| IP Protection Class | IP54 | ||||

| Input method | Capacitive touch-screen | ||||