Hand-guided Workpiece Carriers Become Autonomous Robots

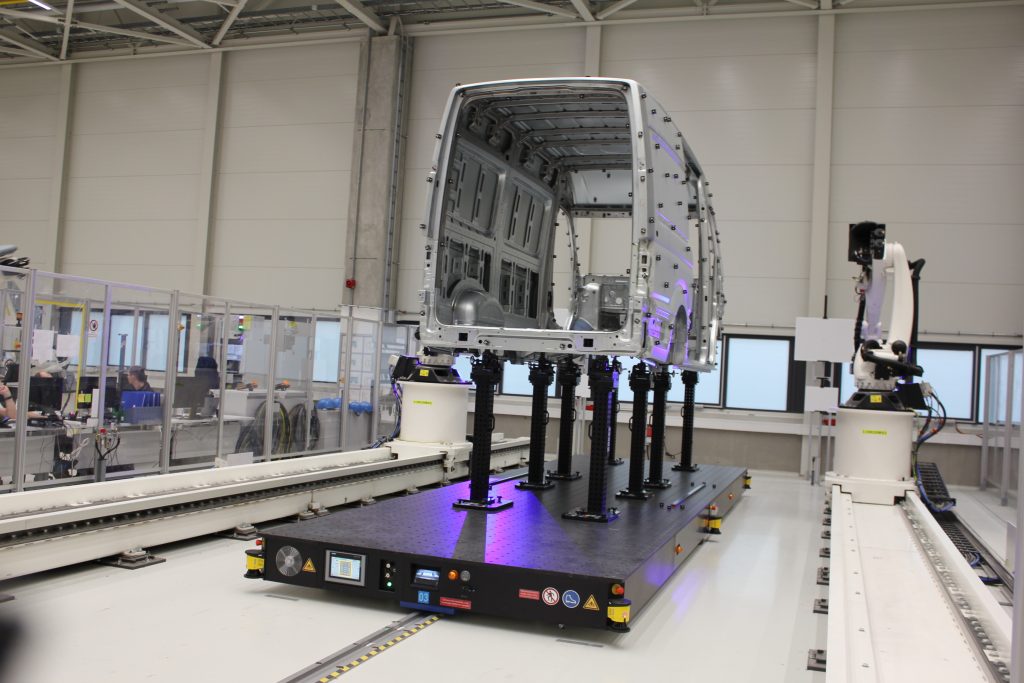

Witte Barskamp GmbH & Co. KG is a specialist for high-precision components, clamping technology and carrier systems for measuring applications. Their portfolio also includes large, mobile aluminium structural plates in sandwich design, which take over the transport of large components between the production line and the measuring cells. Originally, these sandwich plates were moved by remote control before they were provided with an option to upgrade to either rail-bound or transponder-guided driverless systems. Since 2016, however, there has also been the option of having them as fully autonomous mobile robots with AMR control software from Neobotix.

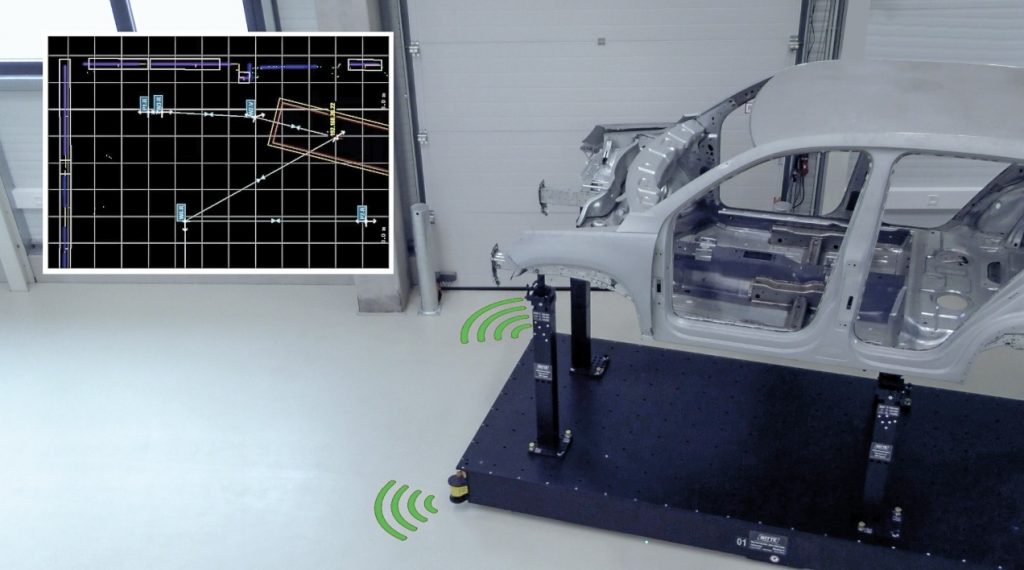

More Flexibility and Less Effort with Laser Based Robot Navigation

The first AMR sandwich panels still use PlatformCtrl, the predecessor to the current and recommended AMR control software PlatformPilot. Even with PlatformCtrl, the set-up effort was reduced considerably, as there is no need for structural changes to the working environment. Even during operation, changes to the routes and adjustments to the parking and measuring positions can be made quickly and easily. Instead of laying new transponders into the hall floor or laying new rail tracks, a few mouse clicks in the graphical user interface are now sufficient to adapt the vehicles to the dynamic conditions.