Automated Testing of Large Concrete Surfaces

Regular inspections are necessary to check for signs of ageing and damage in concrete structures. Sometimes it may be a large area, such as a car park, that needs to be scanned with different sensors. This also has to be done carefully so that no area is left uninspected. In order to ease these demands on the human workers, Neobotix along with the German Federal Institute for Material Research and Testing successfully developed an autonomous solution using the mobile robot MP-500.

A Variety of Sensors ...

The mobile robot features a specialized carrier frame that enables the easy attachment of standardized sensor holders without requiring any tools. This allows for the rapid selection of appropriate sensors for various applications and quick replacement of sensors if needed. During the measurement the robot provides the necessary power to the sensors, stores the measurement data, and also can transmit it live to a host computer for evaluation. Additionally, the robot can synchronize the movement with any necessary actuators, such as raising or lowering measuring heads.

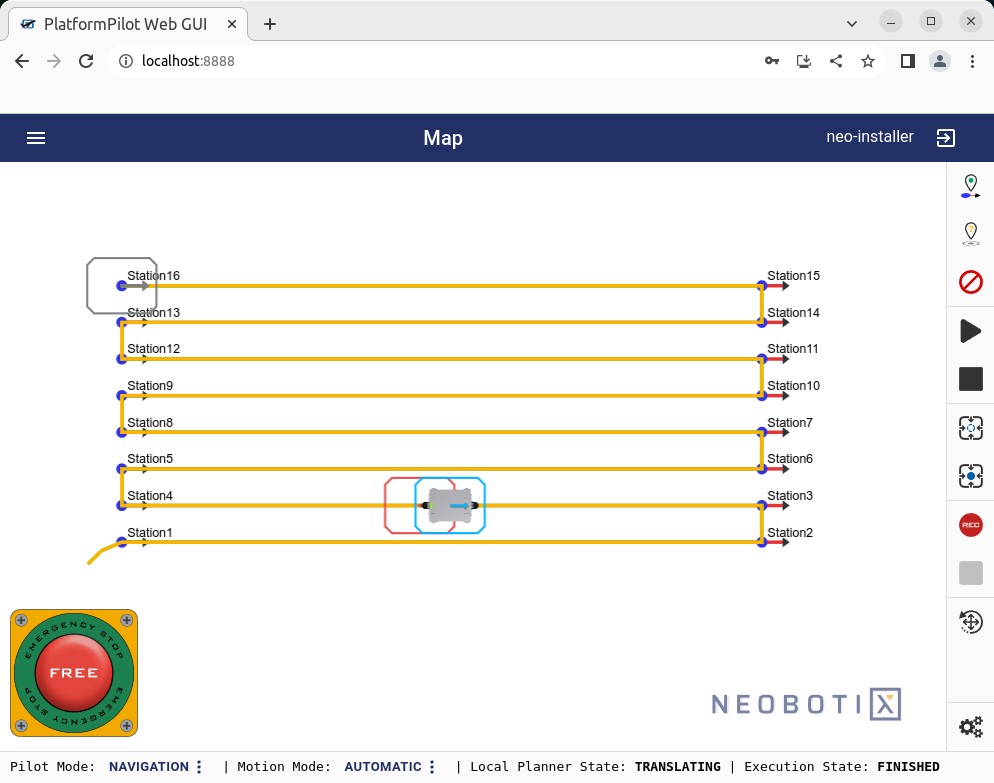

... On Variable Paths

The robot's route is defined purely in software, opening up another area of efficiency improvements. Using the appropriate software tool the operator only needs to define the general measurement or working area. The robot then plans its path automatically. Even fine grids and complex patterns can be generated with the simple push of a button.

Once the robot has been configured and the automated measurement process has been initiated, test specialists can focus their attention on directly analyzing and evaluating the measurement results. This not only saves them significant time but also alleviates physical strain. The interaction between the human operator and the robot enables quicker reopening of roads and structures to traffic than was previously possible.